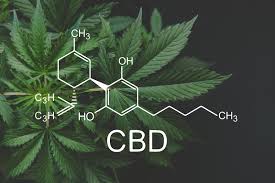

“Cannabinoids” are the naturally arising compounds identified in Cannabis plants. “CBD”, is the acronym for cannabidiol. It is just one of the wide range of cannabinoids identified within marijuana and hemp plants.

Cannabidiol products are accessible from hemp or marijuana which grow domestically and internationally. Because of legal restrictions, many medicinal CBD products (containing less than .3% THC) are sourced from industrial hemp. Fourteen states throughout the USA have provisions for lawful growing and processing of industrial hemp and seeds. Tennessee, Oregon, Kentucky, Colorado and California are a couple of these states. Jeff LaBerge’s business was one of the initial companies to grow industrial hemp in CA legally.

Jeff LaBerge discusses how to obtain CBD from hemp

CBD is obtained from hemp through CO2 or ethanol extraction. The CBDistillery uses CO2 extraction to extract CBD Oil, considering that CO2 extraction is a purer type of removal that filters the hemp plants with regulated temperature level and pressure.

Where the hemp plant grows

Many CBD producers and suppliers choose industrial hemp that grows with organic best practices. However, hemp is not a product that is qualified for USDA organic accreditation.

General recommendations are that CBD products utilized for human health treatment are pesticide-free and non-genetically adjusted, industrial hemp. The plants have to be tested for contaminants. Proper testing cuts down the chances of unfavorable side effects.

Jeff LaBerge encourages buyers to carry out thorough due diligence. It’s important to make sure that only safe solvents are utilized with validated extraction methods.

CO2 and Ethanol Extraction Strategies

Typically speaking, legal regulations mean that the majority of CBD products arrive from the storks or stems of industrial strains of the cannabis plant. These must contain less than .3% THC, which is a requirement for classification as “industrial hemp”. Tetrahydrocannabinol (THC), is the cannabinoid with psychoactive properties.

Ethanol separation

The ethanol extraction process involves the use of the natural solvent ethanol to take out cannabinoids from the hemp plant. Unlike CO2 extraction, this method obtains very high amounts of full-spectrum hemp extract. Ethanol separation can also remove unwanted elements from dried hemp stock, such as chlorophyll; but only if processed at cold temperatures.

CO2 extraction

CO2 extraction is a favored approach due to the fact that it is best for processing smaller amounts of hemp. This solution involves filtering hemp plant components through a matrix of chambers that manages both pressure and temperature level. By changing the units of temperatures and pressure, experienced process operators can seclude cannabinoids at a 90% efficiency.

Post Extraction

Chromatography is the post-extraction procedure. It removes undesirable phytochemicals from the partially processed oil extracts. CBD and other cannabinoids have strong communication responses with the chromatography media; whilst chlorophyll has minimal interaction. Additional refining follows where terpenes can also be separated; the remaining exhausted plant components can be discarded.

Additional refinement is carried out including “decarboxylation”. This gets the cannabinoids to better interact with the endocannabinoid system. In turn, this is better for circulation and absorption throughout the body Jeff LaBerge clarifies. This process transforms CBDA to CBD, which is essentially the removal of acids for better bioavailability.

High-quality decarboxylated CBD hemp oil is suitable for direct intake. However, the taste of this base format has much to be desired. As such, processors generally suspend the CBD in food-grade oils, such as coconut or hemp seed oil. Then it’s packed in Shoals or processed into powder, or slab isolate format for practical storage, transport and consumption.